Description

Introduction

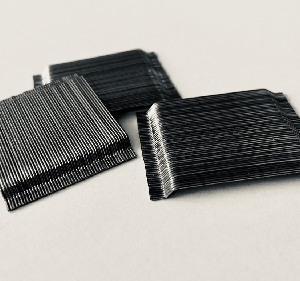

Steel fiber shafts are a type of concrete reinforcement material that is made of high-strength steel wire or sheet. They are typically added to the concrete mix during the mixing process to create fiber-reinforced concrete, which has improved mechanical properties compared to traditional concrete. Steel fiber shafts offer several advantages over traditional reinforcement methods, such as reduced cracking, increased load-bearing capacity, and improved durability. They are commonly used in various applications, including industrial flooring, precast concrete products, tunnels, bridges, and airport runways. Steel fiber shafts provide a cost-effective and efficient solution to enhance the strength and durability of concrete structures, making them a popular choice in the construction industry.

Properties of Steel Fiber Shafts

- High tensile strength: Steel fiber shafts are made of high-strength steel wire or sheet, which provides high tensile strength to the concrete. This results in improved load-bearing capacity and better resistance to cracking and impact.

- Ductility: Steel fiber shafts have a high degree of ductility, which means they can deform under stress without breaking. This property helps to improve the toughness of the concrete and reduces the risk of brittle failure.

- Corrosion resistance: Steel fiber shafts are typically made of stainless steel or coated with a protective layer to enhance their corrosion resistance. This property makes them well-suited for use in harsh environments, such as marine or industrial settings.

- Uniform distribution: Steel fiber shafts are evenly distributed throughout the concrete mixture, which helps to ensure uniform reinforcement and reduce the risk of localized failure.

- Cost-effectiveness: Steel fiber shafts provide a cost-effective solution to traditional reinforcement methods, such as rebar and mesh. They reduce construction time and labor costs, making them a popular choice for many construction projects.

Types of Steel Fiber Shafts

- Hooked-end steel fiber shafts: These steel fibers have a hooked end that provides a mechanical anchorage to the surrounding concrete. This type of steel fiber shaft is commonly used in applications where high toughness and ductility are required, such as industrial flooring and precast concrete products.

- Crimped steel fiber shafts: These steel fibers are crimped to provide better bonding with the concrete matrix. They are commonly used in applications where improved crack resistance and durability are required, such as tunneling and airport runways.

- Straight steel fiber shafts: These steel fibers are straight and provide a uniform reinforcement throughout the concrete matrix. They are commonly used in applications where improved load-bearing capacity and resistance to impact are required, such as bridges and highways.

- Stainless steel fiber shafts: These steel fibers are made of stainless steel and provide excellent corrosion resistance. They are commonly used in applications where exposure to harsh environments, such as marine or industrial settings, is expected.

- Coated steel fiber shafts: These steel fibers are coated with a protective layer, such as epoxy or polymer, to enhance their corrosion resistance and bonding with the concrete matrix. They are commonly used in applications where long-term durability and performance are required, such as high-rise buildings and infrastructure projects.

Applications of Steel Fiber Shafts

- Industrial flooring: Steel fiber shafts are commonly used in industrial flooring applications, such as warehouses, factories, and distribution centers. The steel fibers reinforce to withstand heavy foot and vehicle traffic, reducing the need for maintenance and repairs.

- Precast concrete products: Steel fiber shafts are commonly used in the production of precast concrete products, such as pipes, manholes, and retaining walls. The steel fibers reinforce to withstand the forces of installation and use, reducing the risk of cracking and failure.

- Tunnels: Steel fiber shafts are commonly used in tunneling applications, such as subway systems and underground mines. The steel fibers reinforce to withstand the forces of ground movement and water pressure, reducing the risk of collapse and damage.

- Bridges and highways: Steel fiber shafts are commonly used in the construction of bridges and highways, where they reinforce to withstand heavy traffic, harsh weather conditions, and seismic activity.

- Airport runways: Steel fiber shafts are commonly used in the construction of airport runways, where they reinforce to withstand the forces of aircraft landing and takeoff. The steel fibers also reduce the risk of cracking and improve the durability of the runway.

How to Use Steel Fiber Shafts

- Select the appropriate type and dosage of steel fiber shafts based on the specific project requirements and conditions.

- Add the steel fiber shafts to the concrete mix during the mixing process. Ensure that the steel fibers are evenly distributed throughout the mixture to provide uniform reinforcement.

- Use proper equipment and techniques during concrete placement to avoid segregation and ensure proper consolidation of the concrete. This includes using vibrators or other consolidation methods to ensure that the concrete fills all voids and spaces in the formwork.

- Cure the concrete properly to ensure that it achieves the desired strength and durability. This may involve using curing compounds, wet curing, or other methods to maintain the proper moisture and temperature levels during the curing process.

- Inspect the steel fiber reinforced concrete for any defects or damage after placement and curing. This will help to identify any issues that may need to be addressed before the structure is put into service.

-1-300x300.jpg)

Reviews

There are no reviews yet.