Description

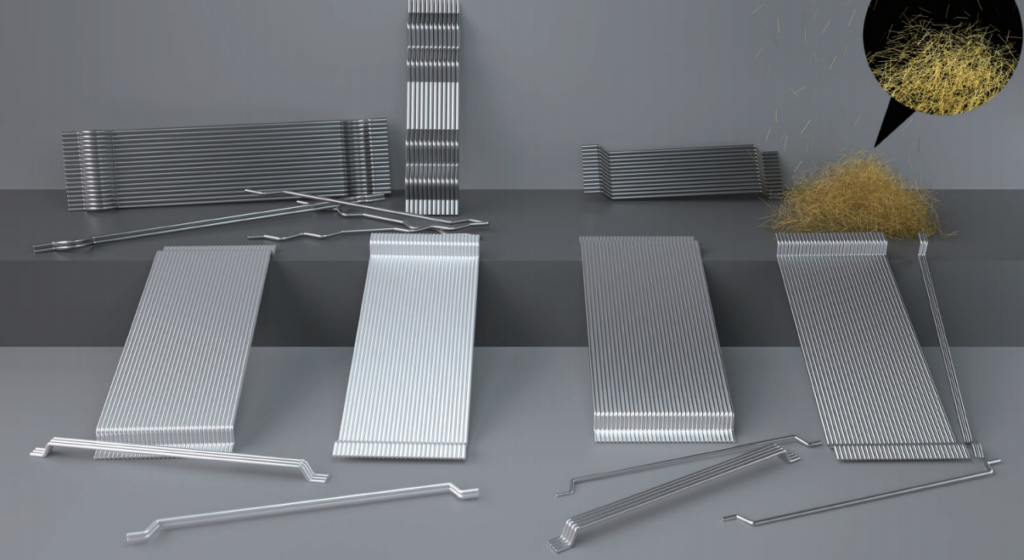

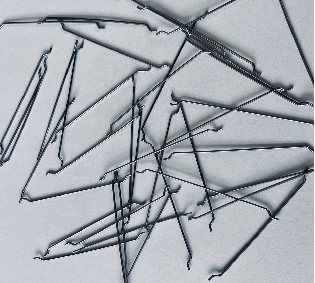

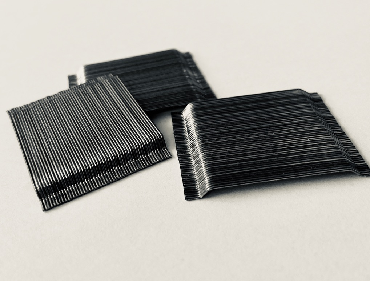

Properties and Types of Steel Fiber

This section discusses the various properties and types of steel fiber, including its tensile strength, ductility, and corrosion resistance. It covers different shapes and sizes of steel fiber, including hooked, flat, and round.

Benefits of Using Steel Fiber

- Increased durability: Steel fiber can significantly improve the durability of concrete structures. It enhances the resistance to cracking and improves the fatigue resistance of the concrete.

- Improved load-bearing capacity: Steel fiber increases the flexural strength and load-bearing capacity of concrete structures. It also enhances ductility and the toughness of concrete.

- Crack resistance: Steel fiber can reduce the formation of cracks in concrete structures, which improves their overall durability and reduces the need for maintenance.

- Corrosion resistance: Steel fiber is corrosion-resistant, which makes it ideal for use in harsh environments such as marine structures, tunnels, and bridges.

- Cost-effectiveness: Using steel fiber can reduce the overall cost of construction projects by reducing the amount of concrete required and the need for additional reinforcement materials.

- Increased construction speed: Using steel fiber in concrete structures can significantly reduce construction time by eliminating the need for additional reinforcement materials and reducing the need for maintenance.

Applications of Steel Fiber

- Concrete flooring: Steel fiber is commonly used in concrete flooring applications, such as industrial floors, warehouses, and parking garages. It enhances the durability and load-bearing capacity of the concrete floor and reduces the need for maintenance.

- Precast concrete: Steel fiber is also used in precast concrete applications, such as precast beams, columns, and panels. It improves the strength and durability of precast concrete and reduces the risk of cracking.

- Shotcrete: Shotcrete is a method of applying concrete using a high-pressure hose. Steel fiber is often added to the mix to improve the strength and durability of the shotcrete.

- Tunnel linings: Steel fiber is used in tunnel linings to enhance their durability and resistance to cracking. It also reduces the risk of spalling and improves the overall safety of the tunnel.

- Bridges and highways: Steel fiber is used in the construction of bridges and highways to enhance their load-bearing capacity and durability. It also reduces the risk of cracking and improves the overall safety of these structures.

- Mining: Steel fiber is used in the mining industry to reinforce shotcrete in underground mines. It improves the durability and safety of the mine and reduces the risk of rock falls and other accidents.

Choosing the Right Steel Fiber for Your Project

- Consider the type of concrete: The type of concrete used in your project will play a significant role in determining the type of steel fiber to be used. For example, if you are using high-strength concrete, you will need a high-strength steel fiber.

- Determine the dosage: The dosage of steel fiber required for your project will depend on the specific requirements of the project, such as the thickness of the concrete and the load-bearing capacity required. Generally, the dosage of steel fiber ranges from 20 to 90 kg/m3.

- Consider the shape and size: The shape and size of steel fiber will depend on the specific requirements of the project, such as the type of reinforcement required and the application. For example, if you are reinforcing concrete flooring, you may need a flat or hooked-end steel fiber.

- Consider the environmental conditions: The environmental conditions of the project site will also play a significant role in determining the type of steel fiber to be used. For example, if the project site is subject to corrosion, you will need a corrosion-resistant steel fiber.

- Consult with experts: Consult with experts in the field of steel fiber reinforcement to determine the best type of steel fiber for your project. They can provide valuable insights and recommendations based on their experience and expertise.

Conclusion:

In conclusion, steel fiber is a versatile and durable reinforcement material that offers numerous benefits compared to traditional reinforcement methods. Understanding the properties and types of steel fiber, along with its various applications and benefits, is essential when considering it for your project. By choosing the right steel fiber for your project, you can ensure its success and longevity.

Reviews

There are no reviews yet.