Description

Introduction of stainless steel fiber for refractory

Stainless steel fiber is a commonly used reinforcement material in refractory materials. They are long and thin fibers pulled out from stainless steel wire ropes, with a diameter typically between 25 to 35 micrometers. The length of stainless steel fibers can be customized according to specific application requirements. The use of stainless steel fibers in refractory materials can provide many advantages.

Here are some common applications and benefits:

- Enhanced Performance: Stainless steel fibers can enhance the strength and durability of refractory materials, especially in high-temperature environments. They can increase the tensile strength and impact resistance of refractory materials while reducing cracking and fragmentation.

- High-Temperature Stability: Stainless steel fibers have high stability at high temperatures and are not easily softened or melted, making them suitable for use in high-temperature environments. These properties make stainless steel fibers widely used in furnaces, kilns, and other high-temperature equipment.

- Corrosion Resistance: Stainless steel fibers are highly resistant to corrosion and can withstand the erosion of acids, alkalis, and other chemicals, making them suitable for use in the chemical industry and other corrosive environments.

- Fire Resistance: Stainless steel fibers can improve the fire resistance of refractory materials, preventing fires from occurring and spreading.

Types of stainless steel fiber for refractory

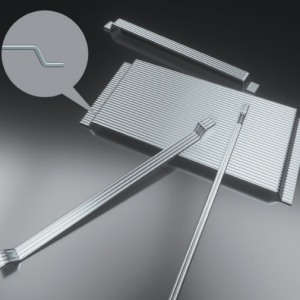

- Straight Stainless Steel Fiber: Straight stainless steel fibers are long, thin fibers that are drawn from stainless steel wire ropes. They are typically used in refractory castables, monolithic refractories, and gunning materials to improve their strength and durability.

- Hooked Stainless Steel Fiber: Hooked stainless steel fibers are similar to straight fibers but have a hooked end. The hooked end helps to anchor the fibers in the refractory material, improving their bonding and strengthening the material.

- Wave Stainless Steel Fiber: Wave stainless steel fibers are crimped fibers that have a wavy shape. The crimped shape helps to improve the bonding between the fibers and the refractory material, enhancing their strength and durability.

- Blended Stainless Steel Fiber: Blended stainless steel fibers are a mixture of different types of stainless steel fibers, such as straight, hooked, and wave fibers. This mixture can provide a combination of different benefits, such as improved bonding and strength.

- Chopped Stainless Steel Fiber: Chopped stainless steel fibers are short, chopped fibers that are added to refractory materials to improve their strength and durability. They are commonly used in shotcrete, gunning materials, and precast refractory shapes.

.jpg)

Advantages

- Increased Strength: Stainless steel fiber can significantly increase the strength and durability of refractory materials. It can enhance the tensile and flexural strength of refractory materials, reduce cracking and fragmentation, and increase the overall durability of the material.

- High-Temperature Resistance: Stainless steel fiber has high-temperature resistance, which makes it suitable for use in high-temperature environments. It can maintain its strength and stability even at extreme temperatures, reducing the risk of material failure.

- Corrosion Resistance: Stainless steel fiber is highly resistant to corrosion, making it ideal for use in corrosive environments. It can withstand the erosion of acids, alkalis, and other chemicals, increasing the longevity of the refractory material.

- Fire Resistance: Stainless steel fiber can improve the fire resistance of refractory materials, preventing fires from occurring and spreading.

Benefits of using steel fibers in refractory castables

- Increased Strength: Stainless steel fiber can significantly increase the strength and durability of refractory materials. It can enhance the tensile and flexural strength of refractory materials, reduce cracking and fragmentation, and increase the overall durability of the material.

- High-Temperature Resistance: Stainless steel fiber has high-temperature resistance, which makes it suitable for use in high-temperature environments. It can maintain its strength and stability even at extreme temperatures, reducing the risk of material failure.

- Corrosion Resistance: Stainless steel fiber is highly resistant to corrosion, making it ideal for use in corrosive environments. It can withstand the erosion of acids, alkalis, and other chemicals, increasing the longevity of the refractory material.

- Fire Resistance: Stainless steel fiber can improve the fire resistance of refractory materials, preventing fires from occurring and spreading.

.jpg)

Reviews

There are no reviews yet.