Description

Detail Information

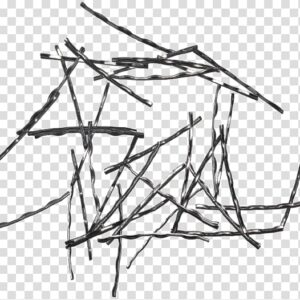

Micro stainless steel fibers are small, thin filaments made of stainless steel that are typically less than 30 microns in diameter. These fibers are used in a variety of applications, including reinforcement of composite materials, conductive coatings, and electromagnetic shielding. The properties of micro stainless steel fibers depend on their composition, diameter, and length. Generally, stainless steel fibers are made from alloys that contain at least 10.5% chromium, which gives them excellent corrosion resistance. Other alloying elements, such as nickel and molybdenum, can improve the strength and toughness of the fibers.

Micro stainless steel fibers can be produced by several methods, including melt spinning, solid-state drawing, and electrospinning. Melt spinning involves melting the stainless steel and then extruding it through a small orifice to form a continuous fiber. Solid-state drawing involves pulling a metal wire through a series of dies to reduce its diameter and increase its strength. Electrospinning uses an electric field to draw a polymer solution or melt it into a fine fiber, which is then coated with stainless steel. The mechanical properties of micro stainless steel fibers depend on their diameter and length. As the diameter decreases, the fiber becomes more flexible and less prone to breakage. However, the strength and stiffness of the fiber also decrease with decreasing diameter. Similarly, longer fibers are generally stronger and stiffer than shorter fibers.

Applications

Micro stainless steel fibers have a wide range of applications in various industries due to their unique properties. Here are some of the common applications of micro stainless steel fibers:

- Reinforcement of composite materials: Micro stainless steel fibers are often added to composite materials such as plastics, ceramics, and concrete to improve their mechanical properties, such as strength, stiffness, and toughness. The fibers also reduce the risk of cracking and increase the durability of the composite material.

- Conductive coatings: Micro stainless steel fibers are used to create conductive coatings for electronic components and devices. The fibers provide electrical conductivity and electromagnetic shielding, which is important in applications such as aerospace, telecommunications, and medical devices.

- Textiles: Micro stainless steel fibers are used in the production of textiles for various applications such as protective clothing and industrial fabrics. The fibers provide excellent strength and durability, making them ideal for applications that require resistance to wear and tear.

- Filtration: Micro stainless steel fibers are used in the production of filters for air, liquids, and gases. The fibers provide excellent filtration properties due to their small diameter and high surface area.

- Energy storage: Micro stainless steel fibers are used in the production of batteries and fuel cells due to their high electrical conductivity and corrosion resistance. The fibers can improve the performance and durability of these energy storage devices.

- Biomedical applications: Micro stainless steel fibers are used in biomedical applications such as tissue engineering, drug delivery, and wound healing. The fibers can be used to create scaffolds for tissue engineering, and they can also be used to deliver drugs directly to specific areas of the body.

Why We Need Micro Stainless Steel Fiber?

Micro stainless steel fibers offer a unique combination of properties that make them useful in various industries. Here are some reasons why we need micro stainless steel fibers:

- Improved mechanical properties: Micro stainless steel fibers can be added to composite materials to improve their mechanical properties such as strength, stiffness, and toughness. This makes the materials more durable and resistant to wear and tear.

- Corrosion resistance: Stainless steel is known for its excellent corrosion resistance, which makes it ideal for use in harsh environments. Micro stainless steel fibers can be used in applications where corrosion resistance is important, such as in the aerospace and marine industries.

- Electrical conductivity: Micro stainless steel fibers are highly conductive and can be used to create conductive coatings for electronic components and devices. This is important in applications such as telecommunications and medical devices.

- Electromagnetic shielding: Micro stainless steel fibers can provide electromagnetic shielding, which is important in applications where electromagnetic interference can cause problems, such as in aerospace and defense.

- Energy storage: Micro stainless steel fibers can be used in the production of batteries and fuel cells due to their high electrical conductivity and corrosion resistance. This can improve the performance and durability of these energy storage devices.

- Biomedical applications: Micro stainless steel fibers can be used in biomedical applications such as tissue engineering, drug delivery, and wound healing. The fibers can be used to create scaffolds for tissue engineering, and they can also be used to deliver drugs directly to specific areas of the body.

Brand Strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress and the products and equipment are taking the lead in the world.

Reviews

There are no reviews yet.