Description

Advantage of hooked end steel fiber

- Improved bonding strength: The hooked shape of the fibers helps to improve their bonding strength with the concrete matrix, ensuring that they remain securely embedded in the concrete and can effectively transfer stresses across cracks.

- Increased tensile strength: Hooked-end fibers can improve the tensile strength of concrete by helping to prevent or mitigate cracks and distribute stresses more evenly across the concrete.

- Enhanced ductility: The hooked shape of the fibers can also enhance the ductility of the concrete, allowing it to deform without cracking under stress and improving its ability to absorb energy.

- Reduced fiber pullout: The hooked shape of the fibers helps to reduce the risk of fiber pullout, which can occur when the fibers are not securely anchored in the concrete and can compromise the overall performance of the material.

- Improved impact resistance: Hooked-end fibers can also improve the impact resistance of concrete, making it more resistant to sudden and heavy loads.

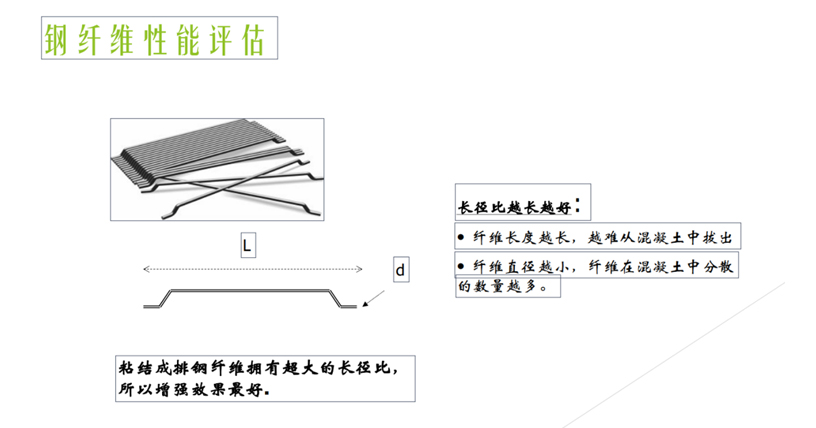

Types of hooked end steel fiber

Several types of hooked-end steel fibers can be used in concrete, each with its unique properties and advantages. Some of the most common types include:

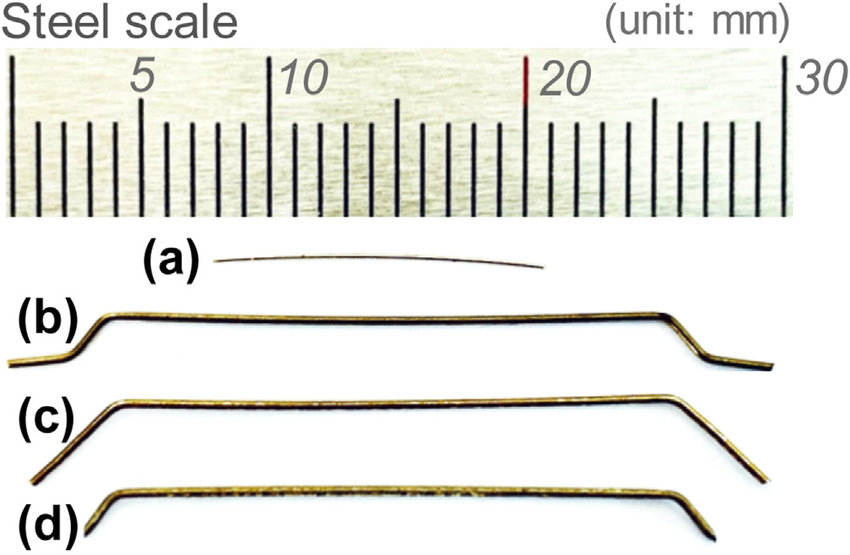

- Straight hooked-end fibers: These fibers have a straight shape with a hooked end, which helps to anchor them in the concrete matrix and improve their bonding strength.

- Wavy hooked-end fibers: These fibers have a wavy or crimped shape, which can enhance their bonding strength with the concrete and improve the ductility of the material.

- Hybrid hooked-end fibers: These fibers are a combination of straight and wavy shapes and are designed to provide a balance of bonding strength and ductility.

- Macro hooked-end fibers: These fibers are larger than other types of steel fibers and are often used in high-stress applications, such as industrial floors and pavements.

- Micro hooked-end fibers: These fibers are smaller in size than other types of steel fibers and are often used in applications where a high surface finish is required, such as architectural concrete.

- Coated hooked-end fibers: These fibers are coated with a layer of material, such as epoxy or polymer, which can enhance their bonding strength with the concrete and improve their corrosion resistance.

Application

As excellent and experienced hooked end steel fiber manufacturers, we have a comprehensive understanding of the properties of the material. Hooked-end steel fibers are commonly used in a variety of concrete applications to improve the mechanical properties of the material. Some of the most common applications of hooked-end steel fibers in concrete include:

- Industrial floors: Hooked-end steel fibers can be added to concrete in industrial flooring applications to improve the durability and impact resistance of the material.

- Pavements and roads: Steel fibers can be added to concrete in pavement and road applications to improve tensile strength and reduce cracking.

- Shotcrete: Hooked-end steel fibers can be added to shotcrete to improve bonding strength and reduce the risk of delamination.

- Precast concrete products: Steel fibers can be added to precast concrete products, such as wall panels and beams, to improve their performance and reduce the need for additional reinforcement.

- Tunnel linings: Steel fibers can be added to concrete in tunnel lining applications to improve the durability and impact resistance of the material.

- Bridge decks: Hooked-end steel fibers can be added to concrete in bridge deck applications to improve tensile strength and reduce cracking.

Ports

Parking Lots

Brand strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress and the products and equipment are taking the lead in the world.

-300x300.jpg)

.jpg)

Reviews

There are no reviews yet.