Description

Advantage Of Glued Steel Fiber In Concrete

Glued steel fiber reinforced concrete (GSFRC) is a type of concrete that incorporates steel fibers that have been chemically bonded to prevent them from clumping together during mixing and placement. Here are some advantages of using glued steel fiber in concrete:

- Increased Strength: GSFRC can increase the strength of concrete by up to 30% compared to traditional concrete. This is due to the added strength and bonding provided by the steel fibers.

- Improved Durability: GSFRC can improve the durability of concrete by reducing cracking and improving resistance to impact, abrasion, and fatigue.

- Reduced Shrinkage: GSFRC can reduce shrinkage and cracking in concrete, which can help to improve its overall durability and longevity.

- Cost-Effective: GSFRC can be a cost-effective alternative to traditional reinforcement methods, such as rebar or wire mesh. This is because it requires less labor and can be mixed and placed more easily.

- Versatile: GSFRC can be used in a wide range of applications, including industrial flooring, precast concrete products, and structural components. It is also suitable for use in harsh environments or applications where exposure to chemicals or moisture is a concern.

Why choose our glued steel fiber in concrete?

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification, and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress, and the products and equipment are taking the lead in the world.

industrial strength

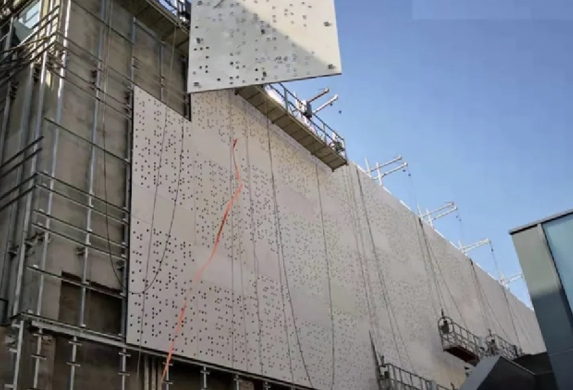

Application of glued steel fiber in concrete

.jpg)

manufacturing environment

.jpg)

manufacturing environment

Application case display

Balcony made of UHPC material

Plates made of UHPC material

.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.