Description

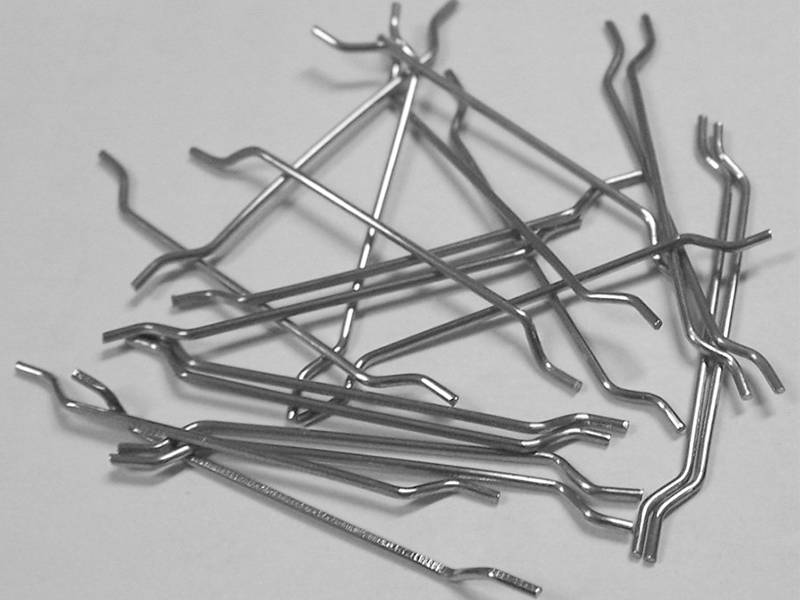

What Is The Hooked End Steel Fiber

Hooked end steel fiber is a type of reinforcement for concrete that is made from high-strength steel. The fibers are typically short, with a length of around 50-60 mm, and feature small hooks on either end. These hooks are designed to anchor the fibers into the concrete matrix, improving the bond between the fiber and the surrounding material. The use of hooked end steel fiber in concrete is becoming increasingly popular, as it offers several advantages over traditional reinforcement materials like rebar.

For example, hooked end steel fiber can be added directly to the concrete mix, eliminating the need for time-consuming installation procedures. Additionally, the use of steel fibers can improve the durability and strength of concrete, making it more resistant to cracking and other forms of damage. Overall, hooked end steel fiber is a valuable and versatile material that can be used in a wide range of applications, from construction and infrastructure to manufacturing and industrial processes. Its unique properties make it an ideal choice for reinforcing concrete and other materials, providing increased strength and durability in even the most demanding environments.

Advantage

The use of hooked end steel fiber in concrete offers several advantages over traditional reinforcement materials like rebar. Here are some of the main advantages:

- Improved durability: Hooked end steel fiber can improve the durability and longevity of concrete by making it more resistant to cracking and other forms of damage. This is particularly important in applications where the concrete will be exposed to high levels of stress or heavy use.

- Increased strength: The use of hooked end steel fiber can increase the strength of concrete, making it more capable of withstanding heavy loads and other forms of stress. This can be particularly useful in construction or infrastructure projects where strength is a critical factor.

- Reduced installation time: Unlike traditional reinforcement materials like rebar, which must be installed manually, hooked end steel fiber can be added directly to the concrete mix. This can significantly reduce installation time and make the process more efficient.

- Improved resistance to corrosion: Steel fibers are less susceptible to corrosion than traditional reinforcement materials like rebar. This can help to extend the lifespan of the concrete and reduce the need for maintenance and repairs over time.

- Versatility: Hooked end steel fiber can be used in a wide range of applications, from construction and infrastructure to manufacturing and industrial processes. Its unique properties make it a valuable and versatile material for reinforcing concrete and other materials.

Specification

| Packaging: | 20kg/bag, 1.25 tons/ton bag |

| Product: | HF-6030,HF-6535,HF-8050,HF-8060,HF-6560 |

| Diameter: | 0.50mm,0.55mm,0.62mm,0.75mm,0.90mm |

| Length: | 30mm,35mm,50mm,60mm |

| L/D Ratio Tensile Strength: | 60,65,80 |

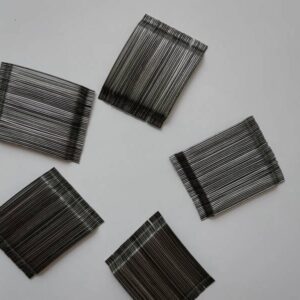

| Type: | Glued/Loose |

| Technique: | Cold Drawn |

| Tensile Strength: | 1150MPa,1100MPa,1000MPa,1300MPa |

| Brand name: | Sino East |

| Place of Origin: | Tianjin, China |

Applications

Hooked end steel fiber can be used in a wide range of applications where reinforcement of concrete is required. Here are some of the main applications of hooked end steel fiber:

- Industrial flooring: Hooked end steel fiber is commonly used in the construction of industrial flooring, where it can provide increased durability and resistance to cracking and other forms of damage. This is particularly important in applications where the flooring will be exposed to heavy machinery or equipment.

- Pavements and roads: Hooked end steel fiber can be used to reinforce pavements and roads, providing increased strength and durability. This can help to extend the lifespan of the pavement and reduce the need for costly repairs and maintenance.

- Bridge decks: Hooked end steel fiber is often used in the construction of bridge decks, where it can provide increased strength and durability. This is particularly important in applications where the bridge will be exposed to heavy traffic or other forms of stress.

- Tunnels: Hooked end steel fiber can be used to reinforce the concrete in tunnels, providing increased strength and durability. This is particularly important in tunnels that are subjected to high levels of stress, such as those used for transportation or mining.

- Precast concrete products: Hooked end steel fiber is commonly used in the production of precast concrete products, such as retaining walls and drainage systems. It can provide increased strength and durability, as well as reduce the need for traditional reinforcement materials like rebar.

Overall, the versatility and strength of hooked end steel fiber make it a valuable material for a wide range of applications, particularly in the construction and infrastructure industries. Its use can help to improve the durability and longevity of concrete structures, reducing the need for costly repairs and maintenance over time.

-300x300.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.