Description

Introduction

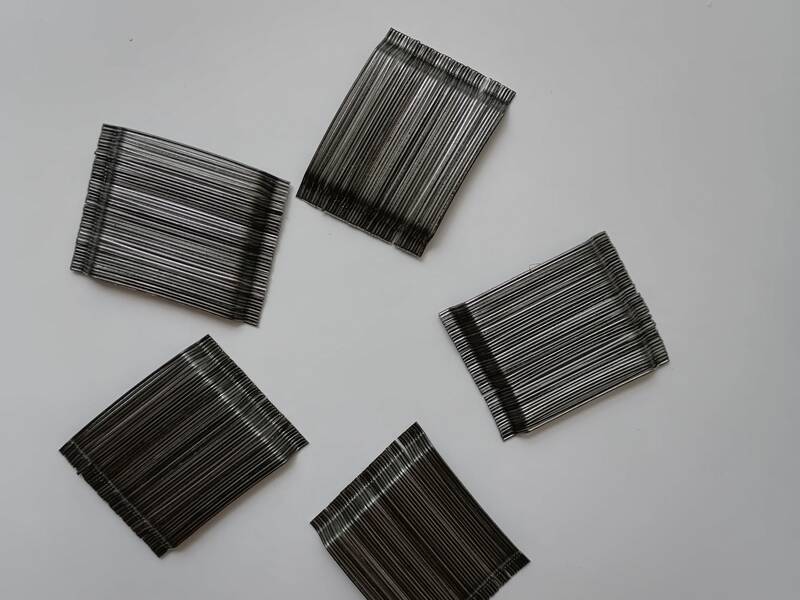

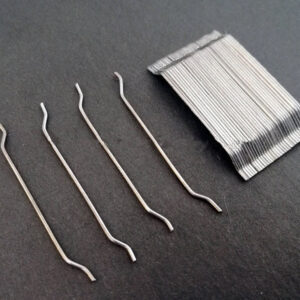

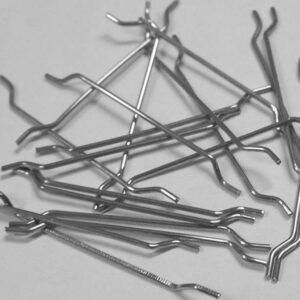

Glued hooked end steel fiber is a type of reinforcement material used in concrete structures. It is made of high-strength steel wires that are shaped into small fibers with hooked ends. The hooked ends of the fibers provide a mechanical bond with the surrounding concrete, which helps to improve the overall strength and durability of the concrete. The fibers are coated with a layer of adhesive material, which helps to bond the fibers together and prevent them from clumping together during the mixing process. The adhesive material also helps to protect the fibers from corrosion, which can occur when exposed to the elements.

Glued hooked end steel fiber is commonly used in various concrete applications, including industrial flooring, precast concrete products, tunnel linings, and shotcrete. It is particularly useful in applications where high strength and durability are required, as the fibers can help to increase the tensile and flexural strength of the concrete. Overall, glued hooked end steel fiber is a robust and reliable reinforcement material that can enhance the performance and longevity of concrete structures.

Advantages

Glued hooked end steel fibers are a type of reinforcement material that is added to concrete to improve its mechanical properties. Here are some advantages of using glued hooked end steel fibers:

- Improved toughness: The addition of glued hooked end steel fibers to concrete improves its toughness and resistance to cracking. This can result in a more durable and long-lasting concrete structure.

- Increased strength: The use of glued hooked end steel fibers can increase the strength of concrete, particularly in tension. This can result in a stronger and more resilient structure.

- Reduced shrinkage: Concrete can shrink as it dries, which can lead to cracking and other issues. Glued hooked end steel fibers can help to reduce shrinkage and minimize the risk of cracking.

- Faster construction: Using glued hooked end steel fibers can speed up the construction process by reducing the need for traditional reinforcement methods such as rebar. This can result in faster construction times and lower labor costs.

- Improved fire resistance: Concrete reinforced with glued hooked end steel fibers can have improved fire resistance, making it a safer choice for structures that may be exposed to high temperatures or fire hazards.

Applications

Glued hooked end steel fibers are a popular reinforcement material that is used in a variety of applications. Here are some common applications of glued hooked end steel fiber:

- Industrial flooring: Glued hooked end steel fibers are often used in the construction of industrial floorings, such as warehouses, factories, and distribution centers. The fibers help to improve the durability and load-bearing capacity of the concrete, making it more resistant to heavy machinery and foot traffic.

- Shotcrete: Shotcrete is a method of applying concrete through a high-pressure hose and glued hooked end steel fibers are often added to the mix to improve its strength and toughness. Shotcrete is commonly used for tunnel linings, retaining walls, and other structures where traditional concrete pouring methods may not be feasible.

- Precast concrete: Glued hooked end steel fibers can be added to precast concrete elements such as walls, beams, and columns to improve their strength and durability. This can help to reduce the risk of cracking and other damage during transportation and installation.

- Concrete overlays: Concrete overlays are used to repair and resurface damaged concrete surfaces, and glued hooked end steel fibers can be added to the mix to improve the performance and longevity of the overlay.

- Bridge decks: Glued hooked end steel fibers are often used in the construction of bridge decks, where they can help to improve durability and resistance to cracking and fatigue.

Overall, glued hooked end steel fibers are versatile reinforcement materials that can be used in a wide range of applications to improve the strength, durability, and performance of concrete structures.

Brand Strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress and the products and equipment are taking the lead in the world.

Reviews

There are no reviews yet.