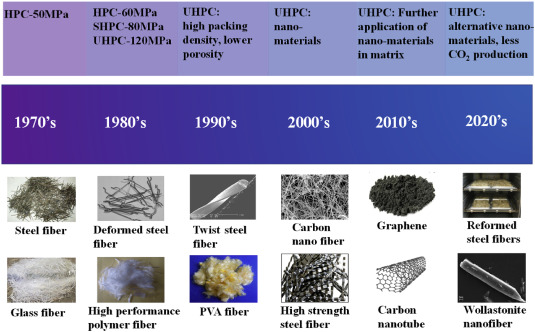

Description

Benefits of High Tensile Steel Fiber

High tensile steel fiber offers several benefits over other types of steel fibers. It has a higher tensile strength, which means it can withstand greater stress and strain without breaking or cracking. This makes it an ideal material for reinforcing concrete and other materials that are subject to heavy loads and stress. High tensile steel fiber also has a higher modulus of elasticity than other types of steel fibers, which means it can deform more before reaching its yield point. This makes it more resistant to fatigue and failure over time.

Applications

1. In Concrete Reinforcement

High tensile steel fiber is commonly used in concrete reinforcement applications, where it is added to the concrete mix to improve its strength and durability. The steel fibers are evenly distributed throughout the concrete, providing reinforcement and preventing cracking and other damage. This makes the concrete more resistant to impact, wear, and fatigue. High tensile steel fiber is used in a wide range of concrete applications, including industrial floors, airport runways, bridge decks, and tunnel linings.

2. In Shotcrete

High tensile steel fiber is also commonly used in shotcrete applications, where it is added to the concrete mix to improve its strength and durability. Shotcrete is a type of concrete that is sprayed onto a surface using a high-pressure hose. The steel fibers are added to the shotcrete mix to provide reinforcement and prevent cracking and other damage. This makes the shotcrete more resistant to impact, wear, and fatigue. High tensile steel fiber is used in a wide range of shotcrete applications, including mining, tunneling, and slope stabilization.

3. In Mining

High tensile steel fiber is also used in various mining applications, where it is added to shotcrete and other materials to improve their strength and durability. The steel fibers are evenly distributed throughout the material, providing reinforcement and preventing cracking and other damage. This makes the material more resistant to impact, wear, and fatigue. High tensile steel fiber is used in a wide range of mining applications, including underground mining, open-pit mining, and slope stabilization.

Properties

Tensile Strength

The tensile strength of high tensile steel fiber is one of its most important properties. Tensile strength refers to the maximum amount of stress that the material can withstand without breaking or fracturing. High tensile steel fiber has a tensile strength of up to 2500 MPa (megapascals), which is significantly higher than other types of steel fibers. This makes it an ideal material for reinforcing concrete and other materials that are subject to heavy loads and stress.

Modulus of Elasticity

The modulus of elasticity of high tensile steel fiber is another important property. The modulus of elasticity refers to the material’s ability to deform under stress and return to its original shape when the stress is removed. High tensile steel fiber has a high modulus of elasticity, which means it can deform more before reaching its yield point. This makes it more resistant to fatigue and failure over time.

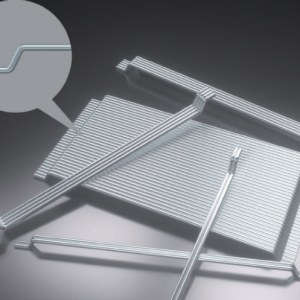

Aspect Ratio

The aspect ratio of high tensile steel fiber is another important property. The aspect ratio refers to the ratio of the fiber’s length to its diameter. High tensile steel fiber typically has a high aspect ratio, which means it is longer and thinner than other types of steel fibers. This gives it a greater surface area, which improves its bonding with the surrounding material and makes it more effective at reinforcing concrete and other materials.

Chemical Composition

The chemical composition of high tensile steel fiber is another important property. High tensile steel fiber is typically made from low-carbon steel or stainless steel, both of which are known for their strength and durability. The chemical composition of the steel can affect the fiber’s strength, ductility, and other properties, making it important to select the right type of steel for the specific application.

Production Ability

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained

ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress, and the products and equipment are taking lead in the world.

Reviews

There are no reviews yet.