Explore the remarkable benefits of incorporating steel fibers in concrete. From enhanced durability and crack resistance to increased structural strength and improved impact and abrasion resistance, steel fibers offer a multitude of advantages.

WHAT IS STEEL FIBER REINFORCED CONCRETE?

Steel fiber reinforced concrete (SFRC) is a composite material comprising cement, aggregates, water, and discontinuous steel fibers. The steel fibers, typically made of carbon or stainless steel, are added to the concrete mixture to enhance its mechanical properties.

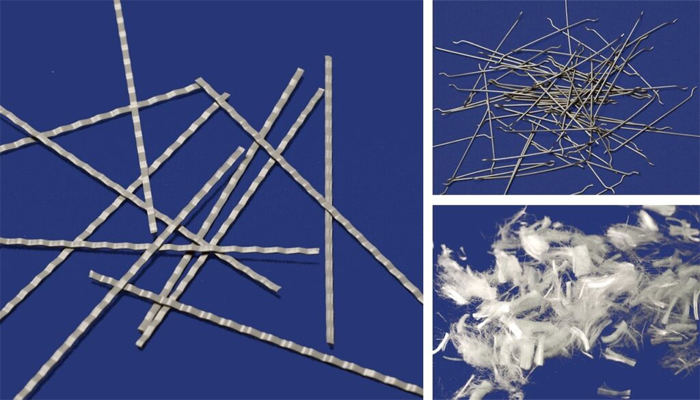

Various types of steel fibers, including hooked, crimped, and straight, are available, each offering specific benefits for different applications.

Uses

Unparalleled Strength, Durability, and Crack Resistance

- Enhanced Strength: The inclusion of steel fibers in concrete significantly improves its tensile strength, enabling it to withstand higher loads and stresses. SFRC exhibits superior structural integrity and can be used in demanding applications that require robust and durable constructions.

- Increased Durability: Steel fiber reinforcement enhances the durability of concrete by reducing cracking and improving resistance to deterioration caused by factors like shrinkage, temperature fluctuations, and chemical exposure. SFRC structures can withstand harsh environmental conditions and maintain their performance over time.

- Crack Resistance: Steel fibers in SFRC act as a reinforcement network, restricting crack propagation and enhancing resistance to cracking. This property makes SFRC ideal for structures subjected to dynamic or cyclic loading, minimizing the risk of structural failure.

Applications

versatility in Construction Projects

- Industrial Flooring: SFRC is widely used in industrial flooring due to its excellent load-carrying capacity, impact resistance, and abrasion resistance. It provides durable and long-lasting flooring solutions for warehouses, manufacturing plants, and logistics centers.

- Infrastructure Projects: SFRC finds applications in infrastructure projects such as bridge decks, tunnels, and pavements. Its high strength and crack resistance make it suitable for structures exposed to heavy traffic loads, seismic activity, and environmental factors.

- Precast Concrete Elements: SFRC is also utilized in the production of precast concrete elements, including panels, beams, and columns. The steel fiber reinforcement enhances their structural performance, making them more resistant to cracking and improving overall durability.

Advantages

- Unmatched Impact Resistance: Steel fibers enhance the impact resistance of concrete, making it more resilient to sudden impacts or dynamic loads.

This property is crucial in structures prone to impact events, including industrial facilities, parking garages, and warehouses. - Exceptional Abrasion Resistance: The incorporation of steel fibers in concrete significantly improves its resistance to abrasion, prolonging the lifespan of surfaces subjected to heavy wear and tear.

This advantage is particularly valuable in applications such as industrial flooring, runways, and roadways, where durability is paramount.

Let Sino East help with your concrete reinforcement needs

- Quality Assurance: Sino East ensures the highest quality standards in its steel fiber reinforcement products. Their materials undergo rigorous testing and adhere to industry regulations, guaranteeing reliable and consistent performance.

- Customer Service: Sino East is committed to providing exceptional customer service. Their team of experts offers technical support, guidance, and customized solutions tailored to your specific project needs. They are dedicated to delivering a seamless experience and ensuring your satisfaction.