This article explores the use of high tensile strength steel fiber to enhance the structural performance of concrete and composite materials. The article highlights the key benefits of using high tensile strength steel fiber, such as increased strength, crack control, improved impact resistance, and design flexibility.

What is High Tensile Strength Steel Fiber?

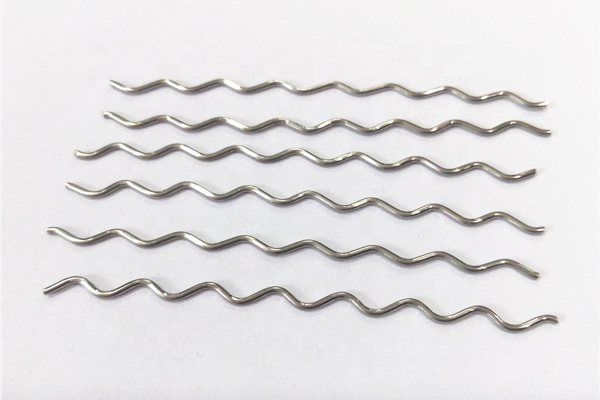

High tensile strength steel fiber is a reinforced material widely used in construction and engineering applications. It consists of small, discrete fibers made from high-strength steel, typically with a diameter ranging from 0.1 to 1.0 mm.

These fibers are added to concrete or other composite materials to enhance their mechanical properties, including tensile strength, flexural strength, and crack resistance. The incorporation of high tensile strength steel fiber offers numerous benefits and opens up new possibilities for creating durable and resilient structures.

Key Benefits of High Tensile Strength Steel Fiber

- Increased Tensile Strength: The addition of high tensile strength steel fiber significantly enhances the tensile strength of concrete, allowing it to withstand higher loads and minimize cracking.

- Improved Flexural Strength: High tensile strength steel fiber reinforces the concrete matrix, increasing its flexural strength and resistance to bending or deformation.

- Crack Control and Prevention: Steel fibers act as reinforcement throughout the concrete, effectively controlling and preventing the propagation of cracks, thereby increasing the overall durability and longevity of the structure.

- Enhanced Impact Resistance: Structures reinforced with high tensile strength steel fiber exhibit improved impact resistance, making them suitable for applications subjected to dynamic loads or heavy vibrations.

- Reduced Maintenance Costs: The incorporation of steel fiber reduces the occurrence of cracks and subsequent maintenance requirements, resulting in cost savings over the structure’s lifespan.

- Design Flexibility: High tensile strength steel fiber enables designers to create thinner and lighter structures without compromising on strength and performance, offering greater design flexibility.

Applications of High Tensile Strength Steel Fiber

High tensile strength steel fiber finds versatile applications in various industries, including:

- Industrial Flooring: Steel-fiber-reinforced concrete (SFRC) is widely used in industrial flooring systems to improve load-bearing capacity, resistance to impact and abrasion, and overall durability.

- Tunneling and Mining: Steel fiber-reinforced shotcrete is employed in tunneling and mining operations, providing structural stability, reinforcement, and crack control in challenging underground environments.

- Precast Elements: High tensile strength steel fiber is utilized in the production of precast concrete elements, such as beams, panels, and bridge components, enhancing their mechanical properties and reducing the risk of cracking during transportation and installation.

- Infrastructure Projects: Steel fiber-reinforced concrete is extensively used in infrastructure projects, including bridges, highways, and airports, to enhance structural performance and ensure long-term durability.

- Residential and Commercial Construction: High tensile strength steel fiber is increasingly incorporated into residential and commercial construction projects to improve the strength and durability of foundations, walls, and slabs.

In conclusion, high tensile strength steel fiber offers remarkable benefits in enhancing the structural performance of concrete and composite materials. Its ability to increase tensile and flexural strength, control cracking, and improve impact resistance makes it a valuable choice for a wide range of applications.

From industrial flooring to infrastructure projects, the incorporation of high tensile strength steel fiber ensures stronger, more durable, and longer-lasting structures. Explore the possibilities of high tensile strength steel fiber and elevate your construction projects to new levels of strength and resilience.