Micro steel fiber brass coated is a high-performance concrete additive that improves the durability, strength, and ductility of concrete structures. This article explores the benefits of using micro steel fiber brass coated in concrete, its manufacturing process, and its applications in various construction projects.

Introduction:

Concrete is one of the most widely used building materials in the world. Its versatility, affordability, and durability make it a popular choice for construction projects of all sizes. However, even the strongest concrete can still be prone to cracking, especially in high-stress areas. This is where micro steel fiber brass coated comes in – it is a type of reinforcement that can be added to concrete to enhance its strength and durability.

What is Micro Steel Fiber Brass Coated?

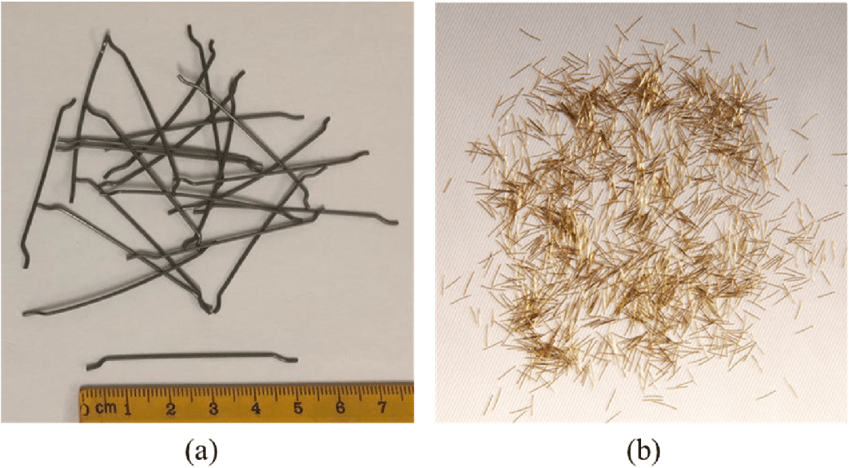

Micro steel fiber brass coated is a type of reinforcement made from small steel fibers that are coated with a layer of brass. The brass coating protects the steel fibers from corrosion and oxidation, making them more durable and long-lasting. Micro steel fiber brass coated is typically added to concrete mixes in small quantities, usually less than 1% by volume.

Benefits of Using Micro Steel Fiber Brass Coated in Concrete:

- Improved Durability: Micro steel fiber brass coated enhances the durability of concrete by reducing cracking and increasing its resistance to impact and abrasion.

- Increased Strength: The addition of micro steel fiber brass coated to concrete increases its tensile and flexural strength, making it more resistant to bending and breaking.

- Enhanced Ductility: Micro steel fiber brass coated increases the ductility of concrete, allowing it to deform without breaking.

- Reduced Maintenance Costs: The enhanced durability and strength of concrete reinforced with micro steel fiber brass coated can reduce the need for maintenance over the lifetime of the structure.

Manufacturing Process of Micro Steel Fiber Brass Coated:

The manufacturing process of micro steel fiber brass coated involves several steps:

- Cutting the steel fibers to the desired length.

- Coating the steel fibers with a layer of brass using a specialized process.

- Drying the brass-coated steel fibers to remove any moisture.

- Packaging the micro steel fiber brass coated for distribution to concrete producers.

Applications of Micro Steel Fiber Brass Coated:

Micro steel fiber brass coated is used in a wide range of construction projects, including:

- Industrial Flooring: Micro steel fiber brass coated is used to reinforce concrete in industrial flooring applications, where heavy machinery and equipment may cause high-stress areas.

- Bridge Decks: Micro steel fiber brass coated is used to reinforce concrete in bridge decks, where exposure to the elements and heavy traffic can cause deterioration and cracking.

- Parking Garages: Micro steel fiber brass coated is used to reinforce concrete in parking garages, where exposure to salt and other chemicals can cause corrosion and damage.

Conclusion:

Micro steel fiber brass coated is an effective and reliable solution for enhancing the durability, strength, and ductility of concrete structures. Its unique properties make it a popular choice for a wide range of construction projects, from industrial flooring to bridge decks and parking garages. By adding micro steel fiber brass coated to concrete mixes, builders, and engineers can ensure that their structures are strong, resilient, and long-lasting.