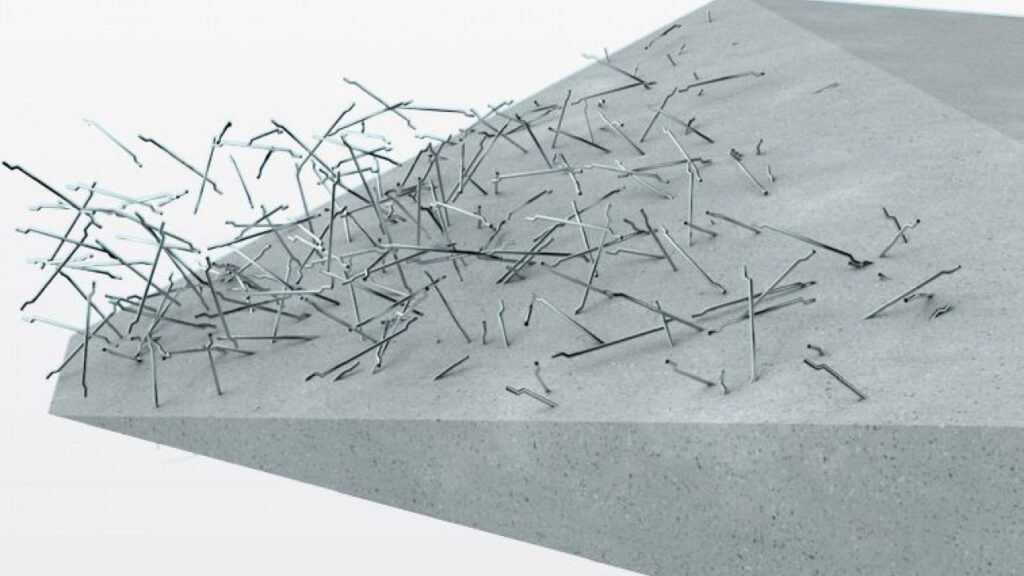

High tensile strength steel fibers are a popular addition to concrete, as they can significantly improve its mechanical properties. These fibers are made from high-quality steel and can be added to the concrete mix to increase its tensile strength, durability, and ductility. In this article, we will explore the properties of high tensile strength steel fibers and how they can benefit concrete structures.

Introduction:

Concrete is a widely used construction material due to its strength, durability, and low cost. However, it has limitations in terms of tensile strength and ductility. To overcome these limitations, high tensile strength steel fibers are often added to the concrete mix. These fibers can improve the mechanical properties of concrete and make it more suitable for various construction projects. Let’s discuss high tensile strength steel fiber properties.

.jpg)

What are High Tensile Strength Steel Fibers?

High tensile strength steel fibers are small, thin, and discrete elements that are added to the concrete mix. These fibers are made from high-quality steel and have a tensile strength of at least 1000 MPa. They are typically 25-50 mm in length and 0.25-1.0 mm in diameter. The fibers can be straight or wavy, and they are uniformly distributed throughout the concrete matrix.

Properties of High Tensile Strength Steel Fibers

High tensile strength steel fibers have several properties that make them an excellent addition to concrete. Firstly, they improve the tensile strength of the concrete, which is crucial in preventing cracking and failure under tension. Secondly, they increase the durability of the concrete, making it more resistant to wear, abrasion, and corrosion. Thirdly, they improve the ductility of the concrete, allowing it to deform without cracking under stress. Finally, they enhance the impact resistance of the concrete, making it more resistant to sudden and heavy loads.

Benefits of High Tensile Strength Steel Fibers in Concrete

The addition of high tensile strength steel fibers to concrete can have several benefits. Firstly, it can reduce the amount of steel reinforcement required, leading to cost savings and reduced construction time. Secondly, it can improve the performance of the concrete, making it more suitable for high-stress applications such as bridges, tunnels, and high-rise buildings. Thirdly, it can increase the service life of the concrete, resulting in lower maintenance costs over time. Finally, it can improve the safety of the concrete, reducing the risk of catastrophic failure.

Examples:

High tensile strength steel fibers have been used in several high-profile construction projects around the world. For example, the Dubai Mall in the United Arab Emirates, one of the largest shopping malls in the world, utilized high tensile strength steel fibers in its concrete mix to improve its strength and durability. The fibers were added to the mix in a ratio of 35 kg/m3, resulting in a concrete mix with a compressive strength of 60 MPa and a tensile strength of 5 MPa. Similarly, the Burj Khalifa, the world’s tallest building, used high tensile strength steel fibers in its concrete mix to enhance its mechanical properties and improve its safety.

.jpg)

Conclusion:

High tensile strength steel fibers are an excellent addition to concrete due to their ability to improve its mechanical properties. These fibers can enhance the tensile strength, durability, ductility, and impact resistance of the concrete, making it more suitable for various construction projects. The use of high tensile strength steel fibers in concrete can lead to cost savings, improved performance, increased service life, and enhanced safety. As such, it is a popular choice for engineers and builders around the world.