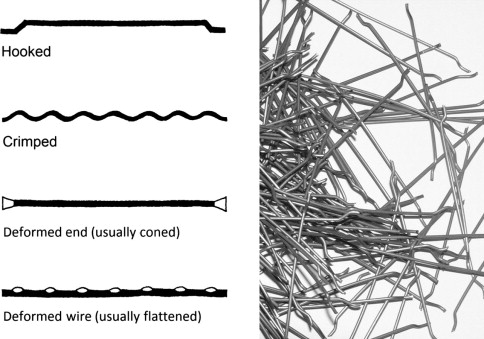

Steel fibre is a popular material used in concrete reinforcement, providing improved strength, durability, and resistance to cracking. However, with several types of steel fibre available, it can be challenging to choose the right one for your project. In this comprehensive guide, we’ll explore the four main types of steel fibre: hooked-end, straight, crimped, and deformed.

Introduction to Steel Fibre for Concrete Reinforcement

Steel fiber is a widely used material in the construction industry for concrete reinforcement. It is a type of reinforcement that is added to concrete to improve its strength, durability, and resistance to cracking. There are several types of steel fiber available, each with its unique characteristics and applications.

Types of Steel Fibre

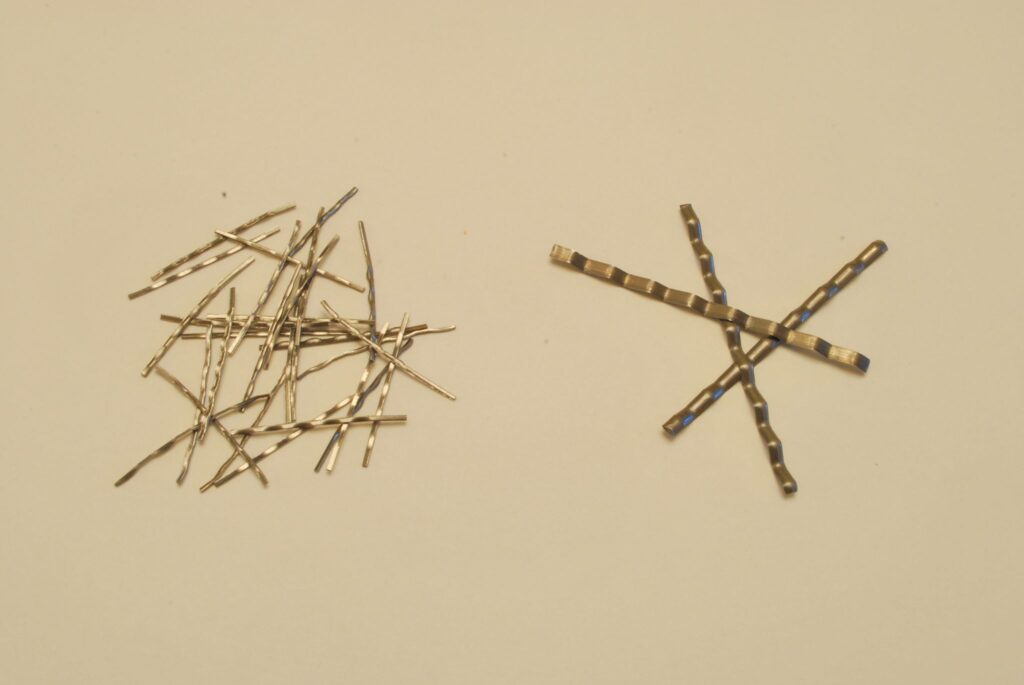

Hooked-end steel fiber is the most commonly used type and has strong bonding properties with concrete. Straight steel fiber is ideal for thin concrete structures and has a smooth surface that reduces friction. Crimped steel fiber improves the toughness of concrete and is suitable for high-impact applications. Deformed steel fiber has a unique shape that enhances its bonding properties with concrete.

Hooked-End Steel Fibre

Hooked-end steel fiber is made by cutting steel wire into short lengths and then cold-drawing them to create a hook shape at one end. This type of steel fiber is commonly used in industrial flooring and shotcrete applications due to its strong bonding properties with concrete.

Straight Steel Fibre

Straight steel fiber is made by cutting steel wire into short lengths and has a smooth surface that reduces friction. This type of steel fiber is ideal for thin concrete structures such as precast concrete panels and overlays.

Crimped Steel Fibre

Crimped steel fiber is made by cold-drawing steel wire to create a wave-like shape. This type of steel fiber improves the toughness of concrete and is suitable for high-impact applications such as tunnel lining and bridge decks.

Deformed Steel Fibre

Deformed steel fiber is made by cold-drawing steel wire to create a unique shape that enhances its bonding properties with concrete. This type of steel fiber is commonly used in precast concrete applications and has good crack-control properties.

Advantages and Disadvantages of Steel Fibre

Using steel fiber for concrete reinforcement has several advantages, including improved strength, durability, and resistance to cracking. However, there are also some disadvantages, including increased material costs and the potential for corrosion.

Advantages of Using Steel Fibre for Concrete Reinforcement

Steel fiber can improve the strength and durability of concrete, making it an ideal material for high-traffic areas such as airports and industrial facilities. It also reduces the risk of cracking and can provide a longer service life for concrete structures.

Disadvantages of Using Steel Fibre for Concrete Reinforcement

The main disadvantage of using steel fiber for concrete reinforcement is the increased material cost compared to traditional reinforcement methods. Steel fiber can also lead to corrosion if not installed correctly or in the right environment.

Applications of Steel Fibre for Concrete Reinforcement

Steel fiber is used in a variety of applications for concrete reinforcement, including industrial flooring, precast concrete, tunnel lining, and bridge decks and roadways.

Industrial Flooring

Steel fiber is commonly used in industrial flooring applications due to its high strength and durability. It can also reduce the risk of cracks and improve the service life of the flooring.

Precast Concrete

Steel fiber is an ideal material for precast concrete applications due to its ability to improve the strength and durability of the concrete. It can also reduce the risk of cracks and improve the overall performance of the concrete.

Tunnel Lining

Steel fiber is commonly used in tunnel lining applications due to its ability to withstand high-impact loads and improve the toughness of the concrete.

Bridge Decks and Roadways

Steel fiber is used in bridge decks and roadways to improve the durability and resistance to cracking of the concrete. It can also reduce the maintenance costs associated with these structures.

Conclusion

Choosing the right type of steel fiber is crucial for achieving the desired results in concrete reinforcement. By considering the specific application, concrete type, and environmental conditions, you can choose the right type of steel fiber for your project. With the right steel fiber, you can improve the strength, durability, and longevity of your concrete structures, ensuring their longevity and reliability.